Projects/ Energetic industry

Automation system for Shulbinsk Hydro Power Station

Customer : JSC «AES Shulba Heat and Power Plant ГЭС», Shulbinsk

Automation Object Description Automation Object Description

Shulba Hydro Power Plant is situated on the river Irtysh. Hydraulic structures consist of solid, by-wash and station parts of the dam. The Hydro Power Plant building adjusts to the station part of the dam. The supply conduits are situated in the dam body. 6 adjustable- blade turbines of ПЛ 100/2556-В45-600 type with capacity 117 Mwatt and water expenditure 300m3/c with the rated head 28m are set in the building of the Hydro Power Plant. Max water head is 28 m. The capacity output in the energy system is carried out in 4 current lines 220 kV.

The outdoor switchgear 220 kV is carried out with the system of transfer bars. The water-wheel alternators work in blocks supplied with the transformers having the capacity of 250Мwatt. 3 whole station house transformers switched through the switches to the current distributors of the generators are set in the Hydro Power station.

|

Automation system requirements

Automation system provides operative and service staff with the exact information which is given in the most convenient form for effective control of workflow when producing energy in normal, malfunction and post fault conditions of Hydro Power station.

|

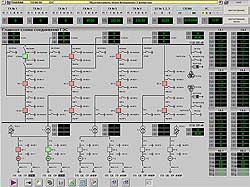

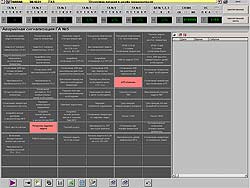

The main symbolic circuit of Hydro Power Station |

System structure

Automation system is based on 10 reserved controllers SIMATIC PCS7 AS414-4-2H with input-output stations ET200M and represents a 2-level distribution system working on-line.

Information exchange between the upper and lower levels is carried out through fiber-optic net Industrial Ethernet provided with «MOXA» commutators.

Input-output stations ET200M supplied with the function of “hot” input-output modules substitution are used.

Information exchange between the input-output stations ET200M and controllers SIMATIC PCS7 AS414-4-2H is carried out through the reserved net Profibus DP.

Current and stored information representation is displayed in 3 engineering work stations of the technological staff and on operation boards TP270 which are situated on boards set near hydraulic units.

To control power quality Simeas P devices are used.

To synchronize all the devices and adapt system time to world time SICLOCK WINGPS device is used.

|

List of functions

Collecting and processing analog and discrete information confirming the state of units and block transformers, house transformers, additional equipment and control systems, actuators state, switching units state and general station devices.

|

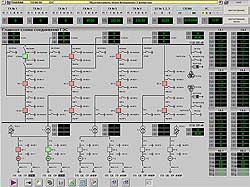

Complex Technical Means Structure Scheme |

Collecting and processing analog and discrete information confirming the state of outdoor switchgear 220 kV, switching units state and electrical measuring data.

Collecting and processing analog and discrete information confirming the state of general station devices, switching units state, actuators and technological and electrical parameters data.

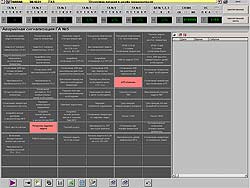

Elaborating precautionary and emergency signaling system informing about technological processes malfunctions, gears and control devices breakdown.

Heat control of hydraulic units and block transformers.

Graphic displaying technological parameters of hydraulic units and block transformers performance giving the possibility to analyze and investigate the reasons of malfunctions.

Storing and recording the information.

Displaying the information to operative and service staff.

On-line control of Shulba Hydro Power Plant technological symbolic circuit

Monitoring system features

Number of input and output controllers

| Input- output/ PLC |

Hydrolic units1..6 |

Control panels 1..3 |

General signals |

Total |

| Analog inputs |

6*117 |

3*17 |

24 |

777 |

| Analog parameters Simeas P |

6*32 |

3*32 |

- |

288 |

| Analog signals total |

894 |

147 |

24 |

1065 |

| Discrete inputs |

malfunctional |

6*60 |

3*17 |

38 |

449 |

| malfunctional(D) |

6*60 |

3*17 |

38 |

449 |

| precautionary |

6*72 |

3*27 |

58 |

571 |

| keys |

6*68 |

3*54 |

276 |

846 |

| Discrete outputs |

6*6 |

3*6 |

6 |

60 |

| Discrete signals in total |

1596 |

363 |

416 |

2375 |

Monitoring system provides controller cyclic inquiry of all the sensors with the inquiry perioв no less than:

- analog sensors 1000 мс;

-discrete precautionary signals system 200 мс;

- discrete malfunction signals 100 мс.

The system was put into operation in March 2008.

|

|

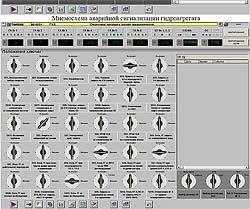

Hydraulic unit malfunction signal system symbolic circuit |

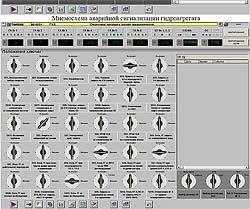

Hydraulic unit keys state symbolic circuit |

|

Automation Object Description

Automation Object Description