| Projects/ Energetic industry

Workflow Automated Control System of the Heat Load Regulator of Boiler №3

Consumer: «Sogrinsk Heat and Power Plant» Ltd., Ust_Kamenogorsk

Automation Object Description

Steam generating unit №3 is the steam-boiler БКЗ-160-100-ФБ of Barnaul Boiler Plant.

The main features of steam generating unit №3 are as follows:

- productivity 160 t/h.

- superheated steam pressure Рshs=101 kilogauss/сm2.

- superheated steam temperature Тshs=540 0С.

- calculating efficiency factor of the boiler = 91,5%.

- calculating temperature of exhaust gases Тeg=123 0С.

The boiler is provided with the two-level circuit of vaporization, it has П-like assembling, monocylindric. The boiler cylinder has the inner diameter is 1600 mm; the wall thickness is 90 mm, made of steel 22К.

The boiler superheater is four-stage, the two-stage water economizer performed as the additional unit in the pipe and connected with the two-stage air heater.

The steam generating unit is provided with the following ancillary equipment:

- two smoke extractors Д-16х2;

- two blower fans ВД-18;

- two ball crushers Ш-10;

- the constant blow separator;

- two dust separators;

- two dust centrifugal classifiers;

- three pipes "Вентури";

- three scrubbers МПВТИ o 2800.

Automation system requirements

The steam generating unit is a dangerous technological object and it consists of different technological units having their own degrees of automation and requiring concerted operation.

The automation system performs the following functions;

- technological data collecting and processing ;

- the data presented as tables, diagrams and symbolic circiuts;

- technological data, warning and emergency signals, system messages archiving;

- remote and automatic control of the manufacturing equipment;

- technological parameters control and elaborating the signaling system in case the parameter exceeding the control bounds;

- heat load regulator of the boiler in automatic mode;

- regulator technological deadlocks in the abnormal mode of the boiler operation.

The automation system provides the operation of the heat load regulation in two modes:

- Basic – the maintenance of the given steam consumption produced by the steam generating unit.

- Regulating – pressure equalization in the steam-main (the system is provided with the choice of the steam-main to be regulated).

|

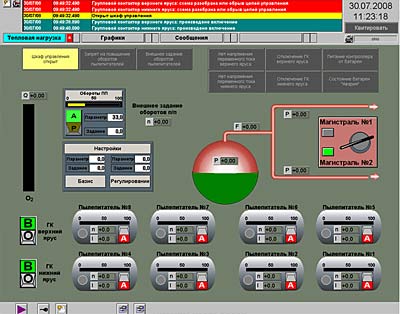

The Process Main Symbolic Circiut

|

The system structure

The automation system is based on the controller SIMATIC S7-300 central processor CPU 315-2DP. The connection with the pulverized coal feeder frequency converters is performed via PROFIBUS DP.

The upper level is the work place of the operator on the base of the PC with the software PCS7 OS Single Station v7.0 The connection between the controller and PC is performed via PROFIBUS DP.

|

Complex Technical Means Structure Scheme

|

The time of the project realization

It was put into operation in the year 2008 |