Projects/ Metallurgy

Automated controlling system for autoclave zinc leaching processes (ACS AZLP)

Client: Chemicometallurgical complex of Balkhash Chemical mining-and-metallurgical works "Zinc Plant" KazakhMys Corporation,

Balkhash, Republic of Kazakhstan

Automation object description

Autoclave zinc leaching facility is designated for zinc extraction from concentrate into solution by means of leaching in high pressure autoclaves. Three independent leaching lines are available in the facility, each of them includes: autoclave, self-evaporation tank and conditioning tank. Zinc leaching is organized according two-stage principle. The facility is designed to provide maximum flexibility, thus each autoclave line can operate on the first or on the second stage, or, even can be reserved. In addition, all measuring and discharge lines are equipped with stand-by pumps. Such flexibility provides possibilities for regular shutdown in order to resetting, technical maintenance or repair without breakdown for the whole facility.

Process objects quantity

| Objects / PLC |

ACS (DCS) |

EPS (DCS) |

Total |

| Analog parameters |

238 |

67 |

305 |

| Discrete parameter |

131 |

4 |

135 |

| Mechanisms |

Mixers |

37 |

0 |

37 |

| Pumps |

51 |

3 |

54 |

| i.f. pumps |

14 |

4 |

18 |

| Cut-off valves |

45 |

61 |

106 |

| Regulating valves |

28 |

21 |

49 |

Belt filters

|

2 |

0 |

2 |

| Control loops |

45 |

27 |

72 |

| Total |

591 |

187 |

778 |

System structure

ACS AZLP comprises two levels of equipment – lower level, information collecting, processing and local management; and upper level, designated for remote management, process observation, archiving and protocoling.

Lower level consists of two subsystems: automated controlling system (ACS – DCS) and emergency protection system (EPS – ESD), based on SIEMENS controllers. ACS subsystem based on SIMATIC S7-400 controller with CPU416-2DP central processor and unreserved decentralized ET200M peripherals. EPS subsystem is based on reserved SIMATIC S7-400H controller with CPU414-4H processor and shiftable decentralized ET200M peripherals.

Upper level appears as three PC with WinCC SIEMENS visualization system.

Data interchange between controllers and workstations is carried out via Industrial Ethernet HSLDO.

The structure of automation system is given on the figure below.

ACS ALZP structure

List of feasible functions

ACS AZLP performs the following functions:

- Admission and processing of analog and discrete signals from technological parameter sensors, diagnostics of PROFIBUS PA sensors and measuring channels running order, adaptation of measured values to adequate conditions (oxygen, steam consumption);

- Displaying the technological data in different formats (on request or automatically) according to operator’s judgment;

- Alarming and registration if parameter reaches emergency or preventive limits;

- Forming and displaying messages protocol, in which are fixed: all messages of preventive and emergency alarming, operator and automation system commands, diagnostic warning about failures;

- Single-circuit and cascaded regulating; providing optimal quality of the process and based on laboratory analyses, automatically calculated predetermined level mode is designated for high-value regulating circuits;

- Automatic (on algorithm) and remote (on operator’s command) management of technological equipment (pumps, mixers, valves, belt filters, thickeners, etc);

- Subsystem of emergency protection ensures shifting of facility equipment into safe mode after emergency or technological blockings are run; also at management controller malfunction;

- Input (by operator) of control results (at a fixed time) or daily average (by the end of a day) results of laboratory analyses;

- Calculation of main technical-and-economic values (energy, raw material consumption), forming of daily summaries on the work of first, second stages of leaching, thickening etc.

- Data archiving subsystem provides archiving of all analog parameters in short archive with query rate = 2, 6 or 30 sec., and 3 days store period; also in long archive with 6 or 30 sec. query rate and storing not less than 32 days; archiving of analyses results, reports and summaries at the beginning of each day with storing not less than 3 months; archiving of messages protocol (last 10 000); displaying archived information or printing out in tables (reports and summaries) or trends (measured values);

- Data interchange between management controllers and ACS AZLP server is run via high speed Industrial Ethernet connection (10 Mbps), in this case data interchange between server and reserved emergency protection is run via reserved connection; in case of malfunction of any CPU or CP controller, data interchange will be continued via other (functioning) channel;

- Data interchange between server and workstations is run via high speed Ethernet (100 Mbps);

- Data interchange between ACS and EPS subsystem controllers is organized via reserved connection; in case of malfunction of any CPU (for EPS) or CP, data interchange will be continued by other (functioning);

- Diagnostic subsystem covers: software environment (errors and malfunctions in software functioning); hardware of lower level – breakdown of processor modules, communication processors, input/output modules, interface modules and others; communication (data interchange) of server and controllers and among controllers; analog disconnexion sensors, short-circuit failures etc.; analog output for line disconnexion; In case of hardware malfunction, data interchange breakdown or program failures, appropriate message is formed.

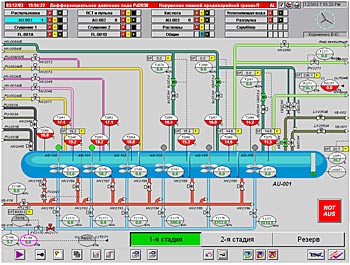

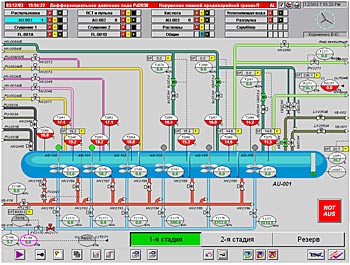

Mnemo of”Autoclave AU-001";

Quantitative and qualitative characteristics of ACS AZLP

ACS AZLP is fed from AC 3~380V/50Hz mains. In order to avoid damage and data loss, hardware of lower level and workstations of upper level are equipped with uninterruptable power supply. Minimum period of buffering in case of electric shutdown is not less than 10 minutes.

Controller input/output quantity:

| Input/ output / PLC |

ACS (DCS) |

EPS (DCS) |

Total |

| Analog inputs |

123 |

51 |

174 |

| Analog outputs |

42 |

22 |

64 |

| Discrete inputs |

543 |

147 |

690 |

| Discrete outputs |

165 |

72 |

237 |

| PROFIBUS PA sensors |

95 |

0 |

95 |

| Analog signals, Total |

260 |

73 |

333 |

| Discrete signals, Total |

708 |

219 |

927 |

ACS AZLP provides cyclic query from controller to all sensors with period not less than:

- Analog sensors ACS 600 milliseconds

- Analog sensors EPS 400 milliseconds

- Analog outputs and discrete ACS inputs/outputs 300 milliseconds

- Analog outputs and discrete EPS inputs/outputs 200 milliseconds

- Max. time of reaction to EPS emergency signal 400 milliseconds

Dynamic characteristics of the system do not exceed the following values:

- Max. rate of data update at operator’s workstation 2 sec

- Max. time of operator’s command transmission and confirmation 2 sec

- Response information transmission (to operator) 2 sec

- Average time of hardware efficiency restoration технических средств 1 hour

Operating life of ACS AZLP – not less than 12 years.

About “SINETIC” Co.Ltd engineering company

Address: Address:

Ust – Kamenogorskб 181/3, prospect Abaja, office 406

Phones: Phones:

(7232) 55-02-04 Reception

(7232) 55-01-20 Director

(7232) 55-03-80 Technical Director

(7232) 55-08-32 Vice technical director

(7232) 23-00-05 Commercial department

(7232) 55-02-60 Technical department

(7232) 23-00-09, 23-00-12 Delivery group

Fax: (7232) 55-02-04 Fax: (7232) 55-02-04

E-mail: ustkam@sinetic.kz E-mail: ustkam@sinetic.kz

|