| Contact phone number | |

|---|---|

|

We attract your attention to the telephone numbers change. For further information... |

|

|||||

|

|||||

| Projects/ Energetic industry Automation System of the Pump Station №6 Customer: JSC "Astana-Teplotransit", Astana

The pump house functionality is pressure maintenance in the pumping head and pressure maintenance in the main return line suction drum. The above mentioned operations provide reliable and qualitative heating of both the Rightbank and the Leftbank parts of the city. The automation system is to control and regulate heating technological parameters in automatic mode. The automation system performs the following functions in the automatic mode:

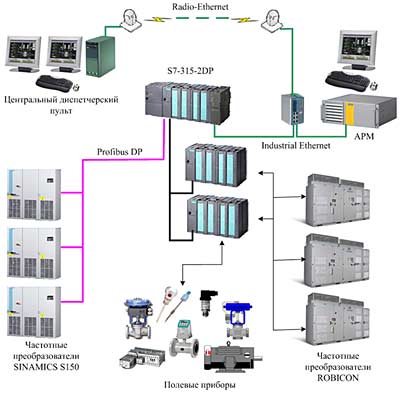

The remote control of the pump house is possible from the operator’s room in the territory of the house and from the central control station; the connection with it is performed via Radio-Ethernet.

The System Structure The automation system is based on the controller SIMATIC S7-300 with the central processor unit CPU 315-2DP. The multiple controller configuration is provided with the interface modules IM361 and IM360.

Complex Technical Means Structure Scheme The time of the project realization

|

070005, Ust - Kamenogorsk, 181/3,

prospect Abaja, office 406,

Tel/fax: +7(7232)41-30-00

E-Mail:ustkam@sinetic.kz