Projects/ Metallurgy

"Automation system for 4th range of РИФ (RIF) -16 floating machines in №3 Main building of “Kazzinc” JSC, Ridder Mining-and-Processing works

Client: Ridder Mining-and-Processing works, Kazzinc JSC.

Procedure description:

Flotation section is used for pulp refinement by dividing mineral fractions according to their wetting properties. In water, fractions selectively stick to air bubbles and being foamed make concentrate. Automation object of the 4th flotation section includes the following equipment:

- РИФ(RIF)-16 floating machine (main and control);

- ФМ(FM)-6,3 floating machine;

- surge box;

- sampling device;

- setting tank;

- sunk basins;

- sunk basin drainage pits;

- sunk basin and drainage pit pumps;

Automation system requirements:

The system allows:

- technological process signals collection from analog and discrete sensors;

- to realize preprocessing of measurements results;

- to present operative information of the technological process in suitable type to service personnel - on screen;

- to issue controlling actions on executive mechanisms in accordance with given algorithm of management;

- to increase technological discipline to account of automatic parameter check;

- to reveal emergencies operatively;

- to complement and change the system without serious technical alterations;

- to form the documents, characterizing move of technological process within a shift, day, etc;

;

Solution and characteristics of automation system:

The automation system is intended for realization of management functions and checking of technological parameters of 4th section in floatation facility. Hardware complex includes: industrial РС, management S7-300 controller, automation devices located on site and panels.

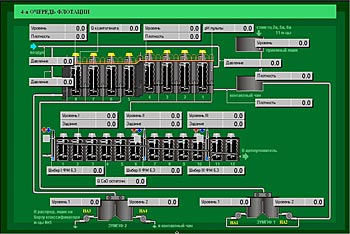

The automation and controlling system consists of two interconnected systems: S7-300 based lower level system and industrial PC based upper level system. Upper and lower levels are interconnected via digital communication channel. The program of lower level is based on STEP-7 software. Upper level program is SCADA "WinCC" based.

Lower level S7-300 controller ensures technological parameters collection and processing, issues controlling actions in accordance with selected management criteria. Controller is located in panel based on constructive elements manufactured by RITTAL.

Upper level computer provides collection; displaying and storage of technological parameters received from controller and appears as equipment operator’s workstation. Start or breakdown of any object, emergency limits and regulator coefficient setting, etc. is made from this place.

Pressing the image of analog input parameter will open passport window of the given signal. The following characteristics are displayed in passport window: full title of input signal, device readings, current scale, transformation method, filtration, device scale, limits and indications.

About “SINETIC” Co.Ltd engineering company

Address: Address:

Ust – Kamenogorskб 181/3, prospect Abaja, office 406

Phones: Phones:

(7232) 55-02-04 Reception

(7232) 55-01-20 Director

(7232) 55-03-80 Technical Director

(7232) 55-08-32 Vice technical director

(7232) 23-00-05 Commercial department

(7232) 55-02-60 Technical department

(7232) 23-00-09, 23-00-12 Delivery group

Fax: (7232) 55-02-04 Fax: (7232) 55-02-04

E-mail: ustkam@sinetic.kz E-mail: ustkam@sinetic.kz

|