| Contact phone number | |

|---|---|

|

We attract your attention to the telephone numbers change. For further information... |

|

|||||

|

|||||

Projects/ Metallurgy Control system of flotation in Concentration plant “Ulba Fluorin complex” Ltd., Kurchatov Customer : “Ulba Fluorin complex” Ltd. Fluorite or fluor-spar(CaF2) is produced at the plant by means of fluorite ore concentration. Fluorite is used in metallurgy as fluxing agent, and to form low-melting slags and when processing sulphuric acid it is used to produce fluor acid. The main part of fluorite concentration is flotation.

Workflow description:

Automation system requirements

Automation system characteristics and structures:

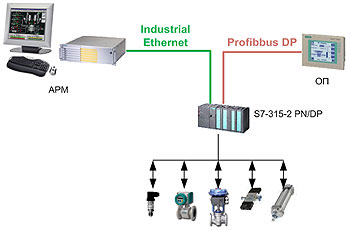

The lower level is based on controller S7-300 – S7-315-2 PN/DP, collecting and processing technological parameters data and regulating the actuators. The lower level program is performed on the software base STEP-7. |

070005, Ust - Kamenogorsk, 181/3,

prospect Abaja, office 406,

Tel/fax: +7(7232)41-30-00

E-Mail:ustkam@sinetic.kz