Projects/ Petroleum chemical industry

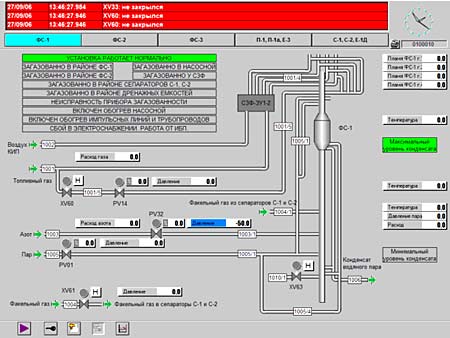

Automated control system of main flaring system and flaring system of acid gas

Client:”Atyrau Oil refinery” Co.Ltd.

Proceduredescription:

Main flare system ensures safe extraction of hydrocarbonic vapor from processing units in cases of disturbances of process conditions, emergency cases, during start-up and shutdown periods.

Main flare system comprises existing and new technological units which will be placed at oil refinery site, except of sulfur production facilities.

Units comprised by the system:

Existing units:

- ЭЛОУ-АВТ-3(ELOU-ABT-3) unit;

- delayed coking unit;

- charred coal baking unit;

- (ЛГ(LG)-35-11/300) reforming unit.

New and modified units:

- ЭЛОУ-АТ-2(ELOU-AT-2) unit;

- combined unit (gasoline and diesel fuel purification/ deparaffination units);

- hydrogen unit.

Moreover, main flare system collects discharges from gas-reagent facility.

Two interchangeable flare stacks (operating and reserved) are designed to provide non-stop operation.

Flare unit comprises:

- main collector O= 1200 mm;

- С-1, С-2 flare gas separators;

- hydrocarbonic condensate pumps Н-1, Н-1а;

- separator – flare stack collectors;

- drainage tank for condensate from flare stack separators, for pipeline and pumps drainage;

- ФС-1, ФС-2 flare stacks.

Acid gas flare system ensures safe extraction of >8% hydrocarbonic gases, during disturbances of process conditions, emergency cases at sulfur production facility.

Automation system requirements:

Automatic Process Control System works out the following tasks:

- realizes centralized checking of technological parameter values, condition of the equipment;

- supports the technological parameters on preset level, fixes parameter declination from preset;

- realizes checking of parameters dangerous declination, determining explosion and fire risk of production process;

- issues controlling actions for executive means preventing occurrence or development of emergency situations with information displaying at operator’s workstation;

- conducts atmosphere gas condition monitoring in dangerous areas, gives danger alarms, management signals for blocking and displays the information to operator;

- conducts anti-fire control;

- conducts archiving of technological parameters;

Solution and characteristics of automation system:

Automation system is based on two SIMATIC S7-300 controllers with CPU 315-2DP central processor and ET200M input/output station for data collection from sensors and executive mechanisms.

Upper level appears as technologist-operator workstation based on WinCC v 6.0 installed PC.

Communication between controller and PC is organized via industrial MPI network

Project implementation period:

Start-up: 2006.

About “SINETIC” Co.Ltd engineering company

Address: Address:

Ust – Kamenogorskб 181/3, prospect Abaja, office 406

Phones: Phones:

(7232) 55-02-04 Reception

(7232) 55-01-20 Director

(7232) 55-03-80 Technical Director

(7232) 55-08-32 Vice technical director

(7232) 23-00-05 Commercial department

(7232) 55-02-60 Technical department

(7232) 23-00-09, 23-00-12 Delivery group

Fax: (7232) 55-02-04 Fax: (7232) 55-02-04

E-mail: ustkam@sinetic.kz E-mail: ustkam@sinetic.kz

|