| Contact phone number | |

|---|---|

|

We attract your attention to the telephone numbers change. For further information... |

|

|||||

|

|||||

| Projects/ Petroleum chemical industry Automated control system of gas pipeline Chinarevsk Gas and Oil Condensate Field (CGOCF) – the system of gas mains Intergas of Central Asia Customer: Zhaikmunai ltd. , Uralsk Automation Object Description

Gas plant construction of Chinarevsk Gas and Oil Condensate Field, summer 2010 The project provides the following technological operations:

To provide max values of the gas pipeline hydraulic efficiency coefficient a periodic gas pipeline reservoir cleaning is performed without gas transporting stopping. To clean gas pipeline reservoir on the linear part there is the location of sites for starting chambers and receiving cleaning devices.

Cleaning device receiving site The tank gas quality and quantity registration is carried out by an automated system of the commerce gas registration unit (CGRU) that was elaborated by SPE “Ozna- Engineering”. The commerce gas registration unit is autonomous and provided with the workstation, data base server, flow-measuring apparatus Floboss 407, a chromatograph and a dew point analyzer. The communication between the commerce gas registration unit and the gas pipeline automated control system is carried out by means of OPC - technology. The System Purpose

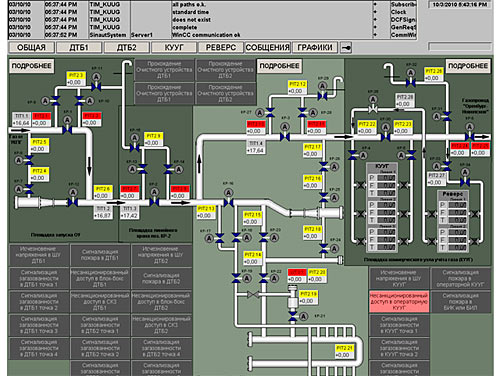

The main symbolic circuit of the gas pipeline workstation

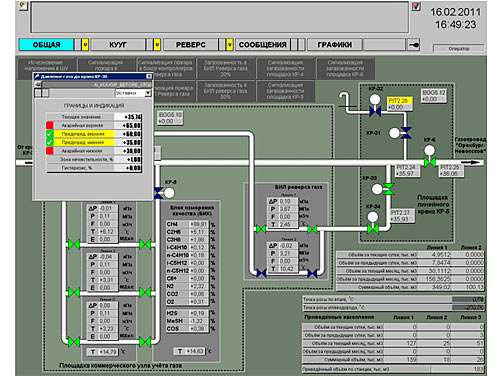

The main symbolic circuit of the workstation at the compressor station of gas main Intergas of Central Asia The System Structure

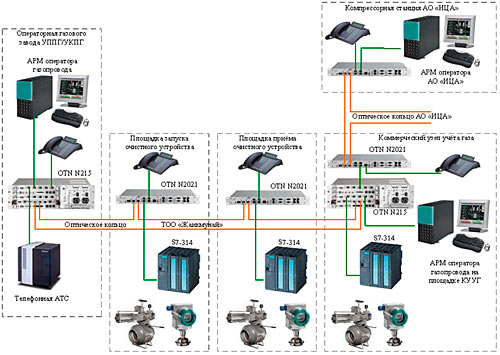

The upper level is the workstations based on the PCs with the set-in software WinCC v6.2. to visualize the workflow each of the computers has a display 19” resolution. There are three workstations located on the following pipeline positions:

For signal transmission of the linear teleautomatics and signals from IP-telephoning fiber-optic communication is used. As a switching equipment Siemens OTN series is used. OTN (Open Transport Network) equipment is a transmitting system based on the latest achievements in fiber optic technologies. Its feature is double-ring attachment that has high network accessibility and different types of services in one and the same network. It transmits different kinds of information such as voice, data and digital video via the network.

Symbolic circuit The system was put into operation in 2011.

|

070005, Ust - Kamenogorsk, 181/3,

prospect Abaja, office 406,

Tel/fax: +7(7232)41-30-00

E-Mail:ustkam@sinetic.kz