Projects/ Energetic industry

The control system of the ore mass flows at the Balkhash Heat and Power Plant (BHPP)

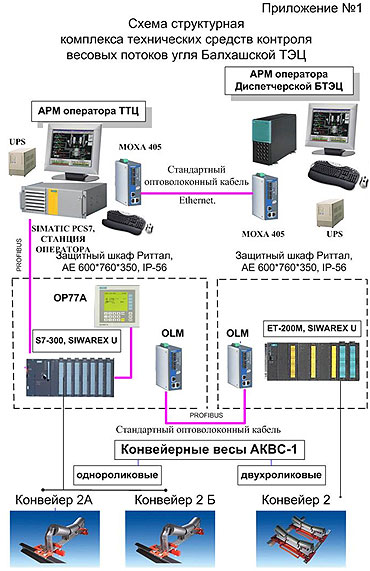

Automated control system of the ore mass flows is a two-level distribution system.

The upper level of the automated control system of the ore mass flows consists of an engineering workstation for an operator at the fuel transportation workshop and for the dispatcher of BHPP. These engineering workstations are connected as a client.

The operator’s engineering workstation at the fuel transportation workshop is carried out on the base of an engineering workstation of the industrial type SIMATIC PCS7 and has the present software and a display 19 inches size. The dispatcher’s workstation at BHPP is carried out on the base of a usual office computer with all the necessary industrial software and has a display 19 inches size.

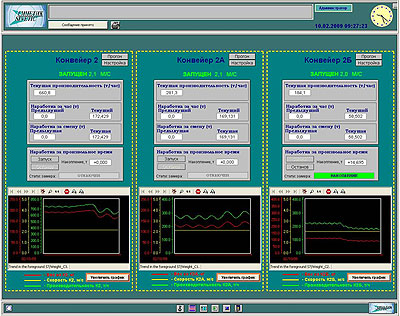

To control the current status of the technological process the operator has all the information in the form of symbolic circuits, diagrams and charts of different refinement degree.

The operator’s panel ОР77В provides programming and visualizing the process when the engineering workstation is off. Instantaneous productiveness and all the accomplished data for an hour, a shift, a month are displayed.

The amount of storing capacity is 6 months and there is a possibility to print all the necessary data.

The lower level includes the controller S7-300 and an input-output station ET200M.

The lower level provides the following functions:

collecting and processing the information which comes from the sensors.

control of the parameters stepping out technological and emergency limits

information exchange with the system upper level and information provision of the workflow current status.

The information exchange between the operator’s panel ОР-77В and S7-300 is carried out via PROFIBUS DP and between input-output stations ЕТ200М and controllers S7-300 via PROFIBUS DP net and fiber optic cable.

Data net exchange

Data transmission between controller S7-300 and the engineering workstation of the fuel transportation workshop and the dispatchers of BHPP is carried out via Industrial Ethernet by means of fiber optic cable with carrying capacity up to 100 Mb per second. The advantage of such a net is the increased noise immunity and the capacity to transmit data at long distances.

Field level

To measure mass of coal conveyors 2А and 2Б one-roller conveyor scales АКВС-1 is used. To measure coal flows on the conveyor № 2 two-roller conveyor scales АКВС-1 are used. The scales operation principle is based on measuring output electric-contact signals from load sensors and rate sensors which change proportionally to the conveyor load and belt movement rate.

Cubicle equipment

The controller, input-output stations ЕТ200М and the equipment to correspond (such as terminal shoes, circuit breakers, etc.) are installed into Rittal cubicles and have the protection rate IP56.

Cubicle ШУ1 with a controller and an operator’s panel in the panel control room of the fuel transportation workshop. Cubicle ШУ2 with station ЕТ200М in Charge Unit №2.

|

Cubicle ШУ-1 in the operator room of the fuel transportation workshop |

| |

|

Symbolic circuit of an operator’s engineering workstation at BHPP |

| |

|

Scales АКВС-1 in operation. BHPP

|

|