Projects/ Municipal housing economy

Pump station №7 automation system

Customer: JSC”Astana- Teplotransit” Astana

Automation Object Description:

Pump station № 7 is located in Astana and supplies delivery water in two directions:

- the feeding main – pumping delivery water in the direct pipeline from Heat Power Plant – 2 in the direction of left bank part of the city.

- the reverse main - pumping delivery water in the reverse pipeline from left bank part of the city in the direction of Heat Power Plant – 2.

Pump station № 7 is a part of complex pump stations JSC”Astana- Teplotransit” and it keeps the mode set by the operation and supervisory service in the heat limits.

The main purpose of the automation system is to coordinate all the equipment at the pump station to keep the set pressure at the sucking of the reverse main and at the head of the feeding main. To keep the pressure the system carries out al the necessary switchings automatically, such as pump starting from the frequency converter, switching the operating from the supplier pump to operation from the converter and the pump stopping.

Pump station № 7

Automation System Purpose

The automation system purpose is to control and regulate the parameters of the heating technological process in the automatic mode. The automation system can carry out the following functions:

- interaction with the local systems control of pumps group start;

- start readiness control and starting the pumps in the automatic order;

- technological pumps stopping in case of emergency values of the technological parameters;

- technological stopping in the automatic mode;

- pressure control at the head of the feeding main by serial starting the pumps from the frequency converter Robicon;

- pressure control at the sucking of the reverse main by serial starting the pumps from the frequency converter Sinamics;

- coordinating automatic switching of the pumps “up” to the operation from the supplier and “down” – to the operation from the frequency converter.

- technological parameters control of the heating process and frequency converters and pumps motors operation control;

- signaling in case the parameter exceeds the set limits.

Remote control and the pump station operation control is possible both from the operaton room at the station territory and from the central supervisory service room the connection with which is carried out via Radio-Ethernet.

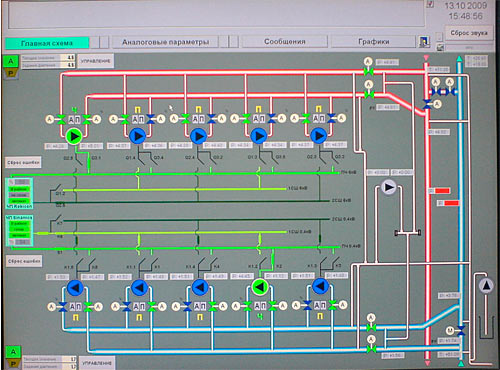

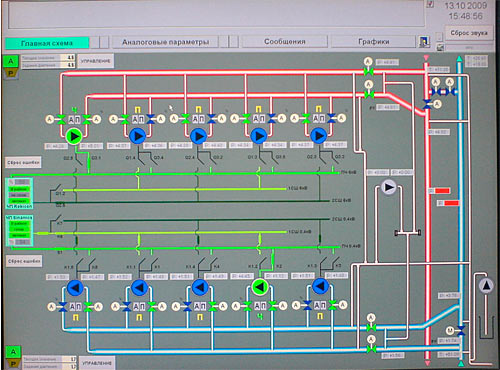

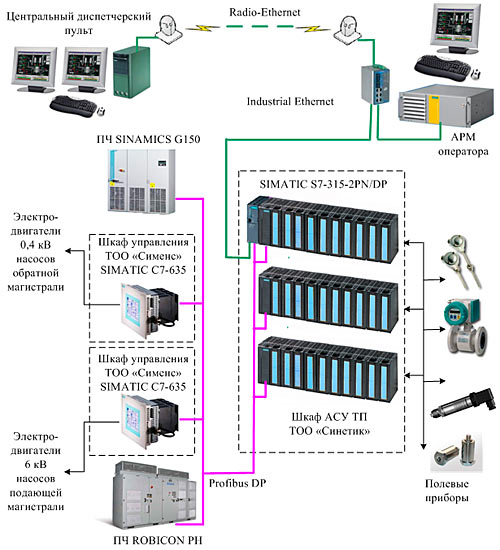

The main symbolic circuit

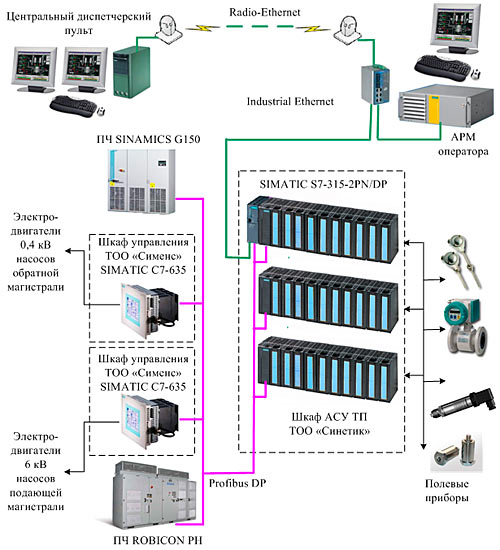

The system structure

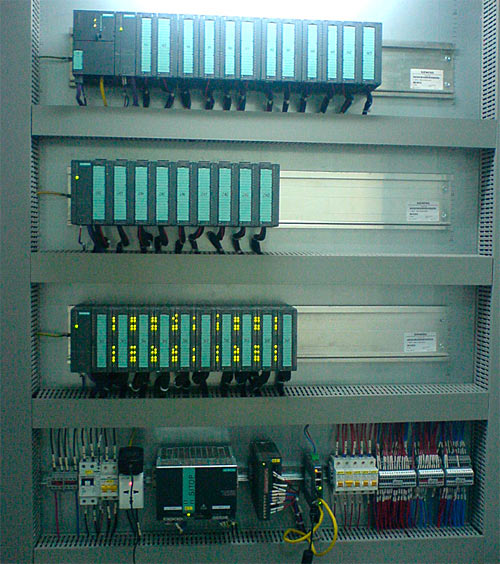

The automation system is based on the controller SIMATIC S7-300 with the central processor CPU 315-2PN/DP. Decentralized system structure is supplied with stations ET200M connected to the central processor via Profibus net.

A frequency converter SINAMICS G150 and ROBICON PH conditions is controlled via Profibus. The communication with the controllers of group starting pumps SIEMENS are carried out via Profibus.

The upper level is the operator’s workstation on the base of the industrial computer SIMATIC RACK PC with the set software PCS7 OS Single Station v7.0 SP1. The communication with the controller and the computer is carried out via Industrial Ethernet.

The communication with the central supervisory station is carried out via special Radio-Ethernet channel.

Symbolic circuit

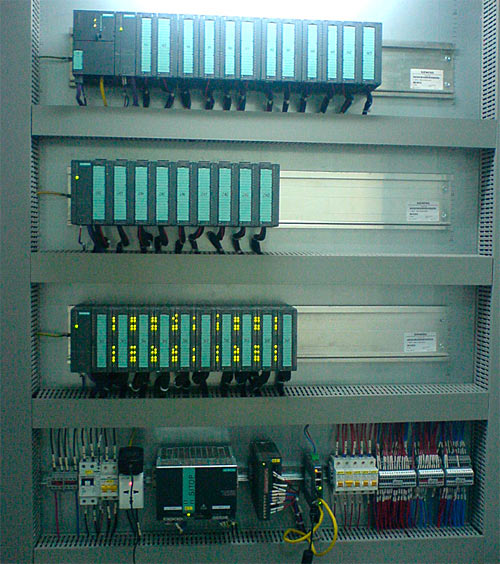

Control cubicle of the automated control system

The introduction of the automated control system was realized cooperatively with Siemens experts whose task was to deliver and parametrizing the frequency converters Sinamics G150 and Robicon PH and setup the local control systems of group start pumps.

The system was put into operation in 2009.

|